Views: 195 Author: Site Editor Publish Time: 2024-10-30 Origin: Site

ARTang is China’s one-stop solution provider for electromagnetic flow meter manufacturer a variety of sizes, materials, and linings to meet customer needs. Electromagnetic flow meter is widely used for the flow measurement of conducting fluids. These are used for the measurement of drinking water as well as wastewater applications, any dirty liquids that are conductive or water-based, raw water, etc.

ARTang is a electromagnetic flow meter manufacturer with full in-house capabilities to produce, assemble, test, and calibrate every flow meter. Few flow meter manufacturers can offer this level of expertise. Electromagnetic flow meters ARTang produces include full-bore electromagnetic flow meter, insertion magmeter, wafer electromagnetic flowmeter, sanitary magnetic flow meter, Split-type electromagnetic flow meter, and battery-powered electromagnetic flow meters.

Chemical Processing: Ensuring precise measurements for complex chemical reactions and maintaining safety and quality standards.

Industrial Water Management: Efficiently managing water usage and treatment processes, ensuring sustainability and regulatory compliance.

Mining & Metal Processing: Monitoring slurry flows and other challenging applications with high accuracy and reliability.

Pulp and Paper: Managing flow rates in pulp production and paper manufacturing processes, ensuring consistency and quality.

Contact Us Today to Enhance your business with our reliable electromagnetic flow meters. Speak with our experts to find the best solution for your needs. We’re here to offer guidance, support, and ensure you get the most out of our products.

Sewage Treatment

Water Monitoring Control

Food & Beverage

Industrial Wastewater

The measuring tube has no obstructive parts, resulting in zero pressure loss and low requirements for straight pipe sections.

This series offers nominal diameters from DN6 to DN2200, with various options for sensor liners and electrode materials.

It is compatible with nearly all corrosive and non-corrosive liquids, making it a popular choice in the process industry.

The measurement results are unaffected by changes in density, viscosity, pressure, temperature, solid impurities, or conductivity (above 5 µs/cm), making it one of the most versatile flow meters.

The transmitter can be combined with the sensor in an integrated design or a separated configuration.

The flow meter supports bidirectional measurement and includes three built-in totalizers: forward, reverse, and net totals. It displays forward and reverse flow and provides multiple output options, including current, pulse, digital communication, HART, and RS485 protocols.

The transmitter uses Surface Mount Technology (SMT) and has self-checking and self-diagnostic functions.

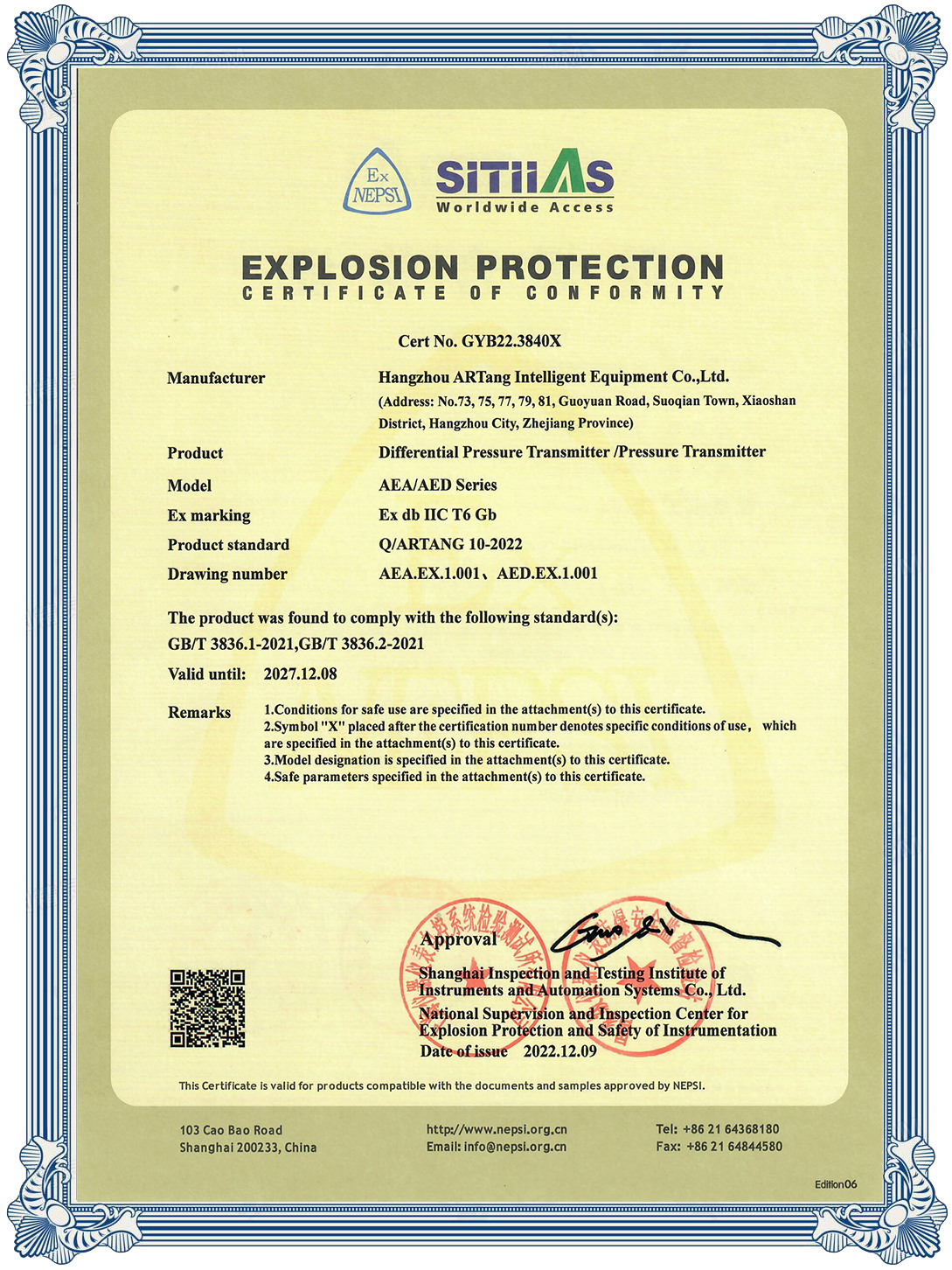

Explosion-proof models are suitable for use in designated hazardous locations.

Additionally, you can contact our experts to choose the right type of magnetic flow meter suitable for your industrial applications. Please visit our website or call us to get more information about high-performance magnetic flow meters.

What's the delivery time for sample order?

The delivery time for a sample order is typically around 7 days.

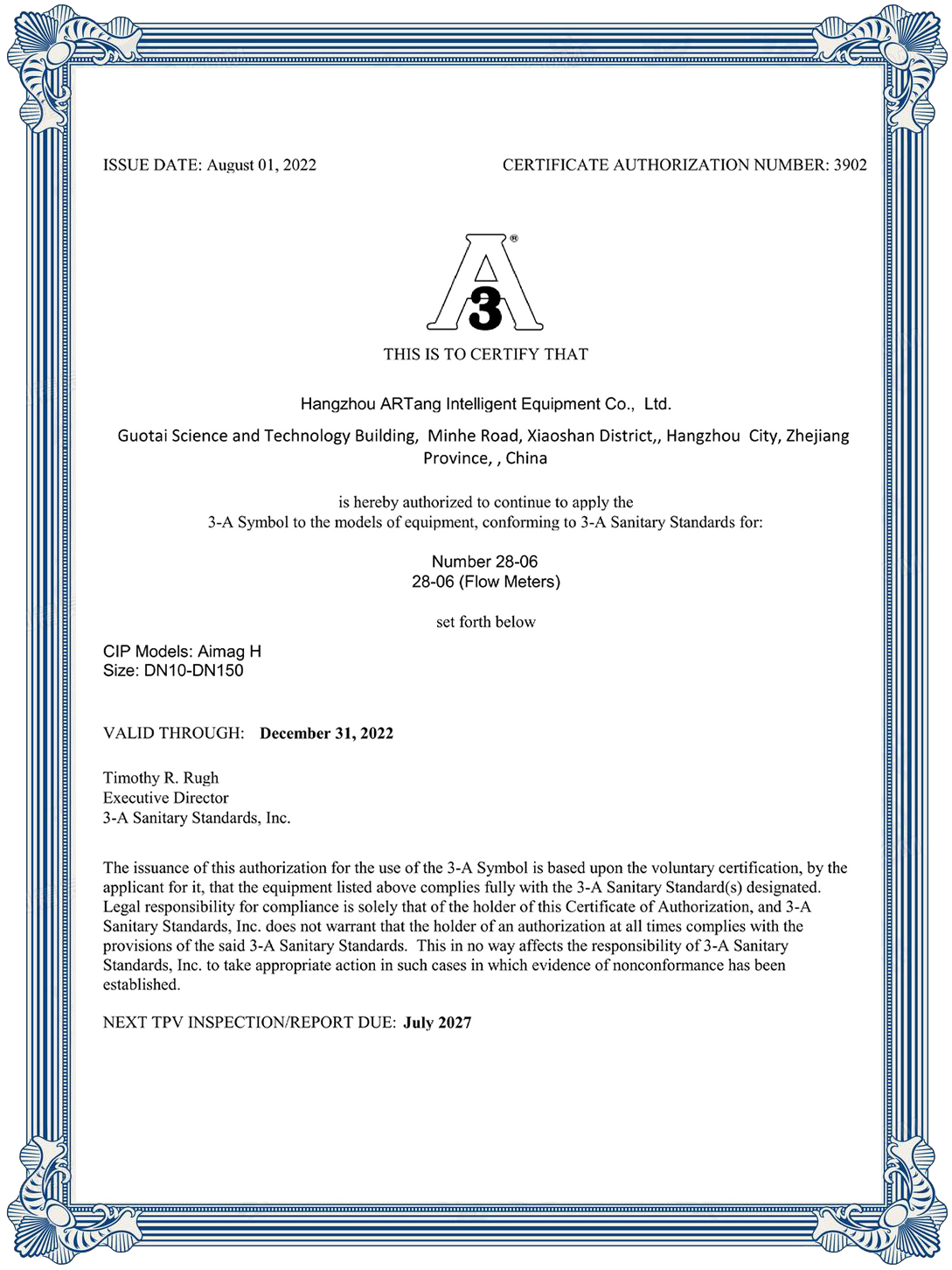

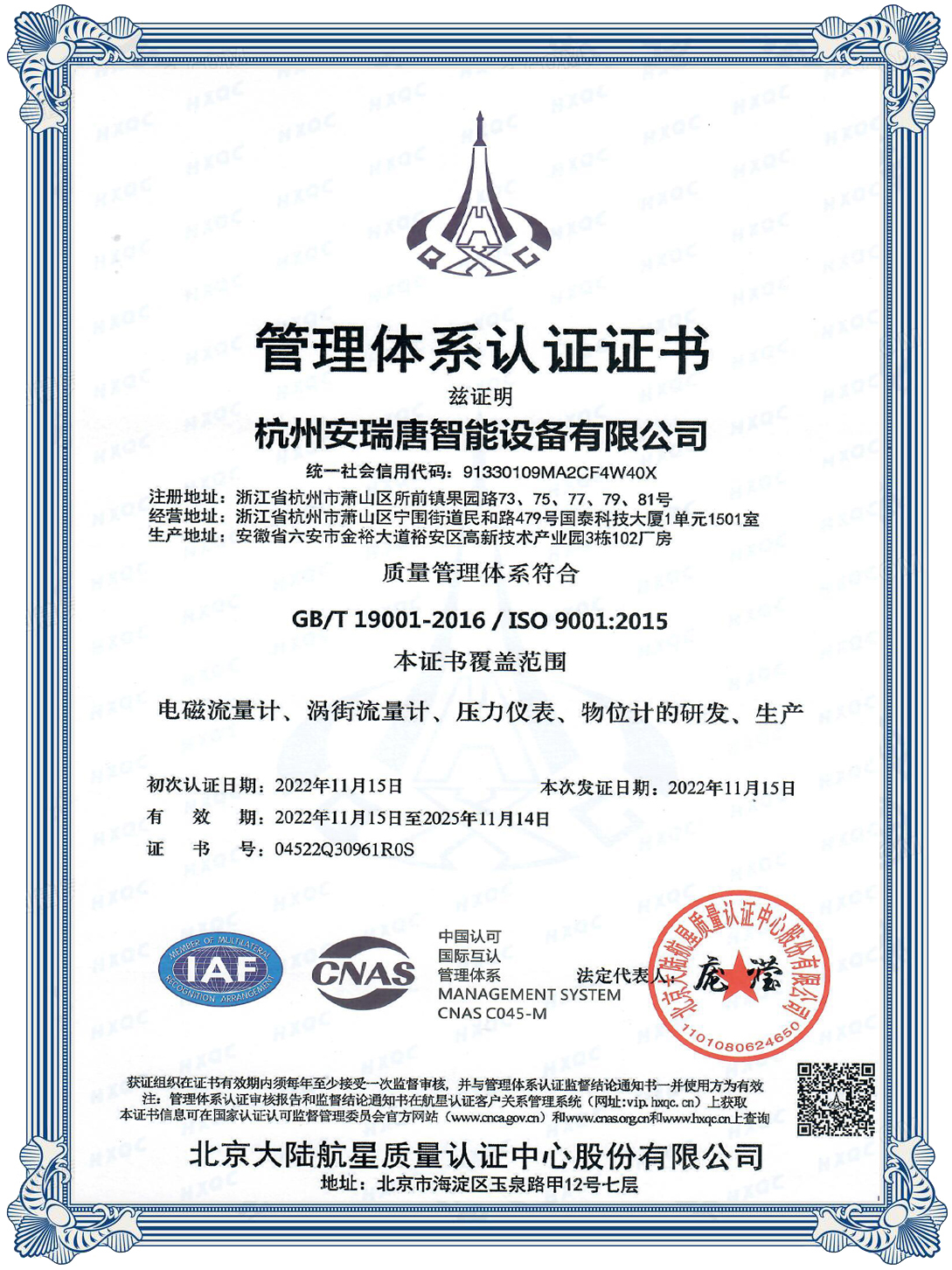

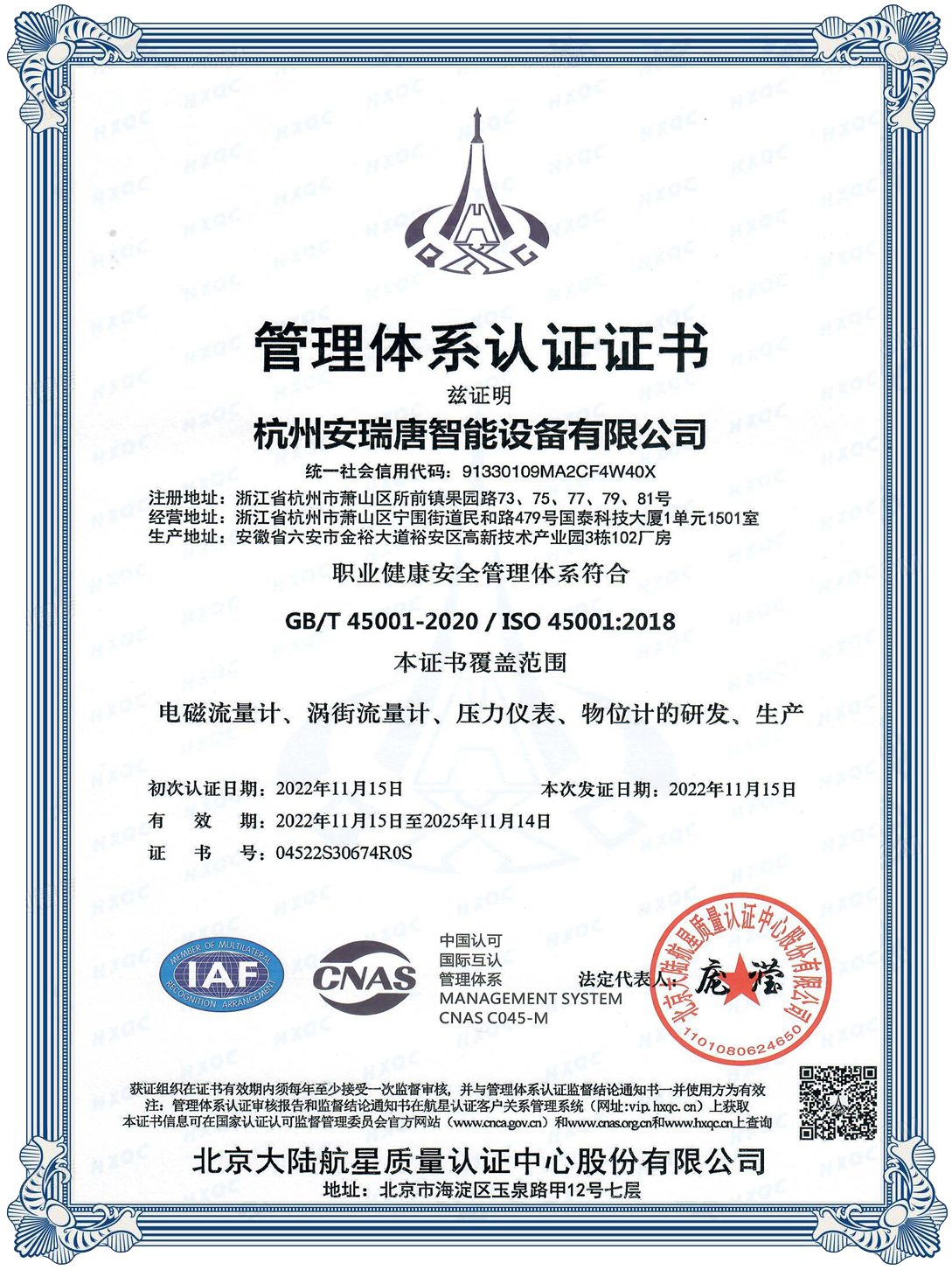

Which certificate you have to your equipment?

Certificates like ISO9001:2008,CE,SIL,EAC,ATEX, 3A.

What is your minimum order quantity?

There are no minimum order quantity, welcome to order according your need.

Are you a manufacturer or a trading company?

We are the source manufacturer of flow meters and recording instruments.

Can you design the machine according to our requirements?

We can customize machines according to customer requirements. Our products offer a variety of options including measurement range, diaphragm material, housing material, accuracy class, IP rating, output signal, and lining material, to suit various working conditions.

1. Product Quality and Accuracy

Accuracy and Stability: The core of a flow meter lies in its measurement accuracy and stability. Choose products that apply advanced technology, offering high precision and reliable stability.

Material Selection: Pay attention to the materials used, such as stainless steel or aluminum alloy, as they greatly impact durability, corrosion resistance, and overall cost.

2. Technical Strength and R&D Capability

R&D Team: Evaluate whether the manufacturer has a professional research and development team, as well as the background and experience of its members.

Technological Innovation: Review the manufacturer’s ability to innovate in the field of flow meters, such as whether they hold proprietary patents or other intellectual property rights.

3. Manufacturing Capacity and Scale

Production Scale: Evaluate the manufacturer’s production capacity, including the number of production lines, the advancement of equipment, and annual output.

Delivery Capability: Understand the manufacturer’s lead times and capacity assurance to ensure they can meet your purchasing needs and deliver on schedule.

4. Market Reputation and Brand Credibility

Customer Reviews: Check user feedback, case studies, and testimonials to understand how other customers evaluate the manufacturer. Such reviews provide a direct reflection of product quality, service level, and overall market reputation.

5. After-Sales Service and Support

Technical Support: Determine whether the manufacturer provides comprehensive technical support, including product selection, installation and commissioning, and troubleshooting.

After-Sales Service System: Quality after-sales service can reduce operating costs and extend the lifespan of your equipment.

In conclusion, when selecting an electromagnetic flow meter manufacturer, you should take into account multiple factors, including product quality, technical strength, manufacturing capacity, market reputation, and after-sales support. By comparing the strengths and weaknesses of different manufacturers, you can choose the one that best meets your needs and ensure the procurement of high-quality, high-performance electromagnetic flow meters.

About ARTang

ARTang is a global leader in measurement instrumentation, services and solutions for industrial process engineering that energizes the transformation of society and industry to achieve a more productive, sustainable future. We provide process solutions for flow, level, pressure, analytics and digital communications, optimizing processes in terms of economic efficiency, safety & environmental impact.